Cooling Tower Motor

Many processes generates excess heat which is cooled by cooled water. The heated water is cooled by cooling towers. The motors for fan of cooling tower works under harsh conditions, the ambient temperature is quite high and highly moist surrounding. “mototek” cooling tower motors are protected with IP55 enclosure protection to minimize the entry of moisture inside the main motor body and terminal box. Efficiency and cooling are batter to withstand the higher ambient temperature. Being under continuous and loaded operation, energy saving is must. It is recommended to use higher efficiency motor for cooling tower. Bearing used are of rubber shield and for better radial loads, to ensure the efficient operation with longer life and minimum friction.

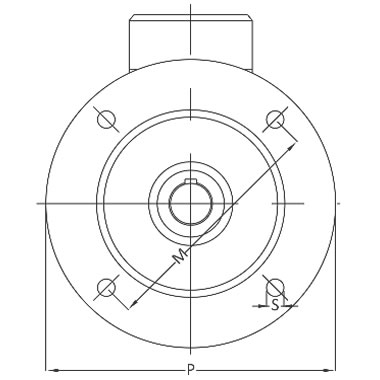

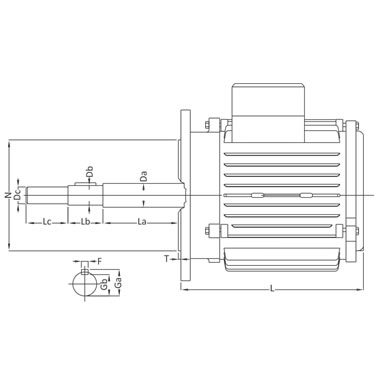

| KW / HP | RPM | FRAME | L | Da | La | Db | Lb | Dc | Lc | M | N | P | S | T | F | Ga | Gb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.37 / 0.5 | 1500 | 71 | 178 | 17 | 55 | 14 | 25 | M12 | 30 | 130 | 110 | 160 | 10 | 3 | 5 | 16 | 11 |

| 0.75 / 1.0 | 1500 | 80 | 200 | 20 | 60 | 19 | 50 | M16 | 35 | 165 | 130 | 200 | 12 | 3 | 6 | 21.5 | 15.5 |

| 0.75 / 1.0 | 1000 | 90S | 230 | 25 | 60 | 24 | 50 | M20 | 40 | 165 | 130 | 200 | 12 | 3 | 8 | 27 | 20 |

| 1.1 / 1.5 | 1000 | 90L | 230 | 25 | 60 | 24 | 50 | M20 | 40 | 165 | 130 | 200 | 12 | 3 | 8 | 27 | 20 |

| 1.5 / 2.0 | 1000 | 100 | 258 | 30 | 60 | 28 | 50 | M24 | 50 | 215 | 180 | 250 | 15 | 4 | 8 | 31 | 24 |

| 2.2 / 3.0 | 750 | 132S | 321 | 40 | 60 | 38 | 50 | M30 | 50 | 265 | 230 | 300 | 15 | 4 | 10 | 41 | 33 |

| 2.2 / 3.0 | 1000 | 112M | 277 | 30 | 60 | 28 | 50 | M24 | 50 | 215 | 180 | 250 | 15 | 4 | 8 | 31 | 24 |

| 3.7 / 5.0 | 1000 | 132S | 321 | 40 | 60 | 38 | 50 | M30 | 50 | 265 | 230 | 300 | 15 | 4 | 10 | 41 | 33 |

| 3.7 / 5.0 | 750 | 132M | 340 | 40 | 90 | 38 | 75 | M30 | 50 | 265 | 230 | 300 | 15 | 4 | 10 | 41 | 33 |

| 5.5 / 7.5 | 1000 | 132M | 340 | 40 | 90 | 38 | 75 | M30 | 50 | 265 | 230 | 300 | 15 | 4 | 10 | 41 | 33 |

| 5.5 / 7.5 | 750 | 160M | 416 | 45 | 90 | 42 | 75 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 12 | 45 | 37 |

| 7.5 / 10.0 | 1000 | 160M | 416 | 45 | 90 | 42 | 75 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 12 | 45 | 37 |

| 7.5 / 10.0 | 750 | 160M | 416 | 45 | 90 | 42 | 75 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 12 | 45 | 37 |

| 9.3 / 12.5 | 1000 | 160M | 416 | 45 | 90 | 42 | 75 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 12 | 45 | 37 |

| 9.3 / 12.5 | 750 | 180M | 467 | 50 | 100 | 48 | 105 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 14 | 51.5 | 42.5 |

| 11.0 / 15.0 | 1000 | 160M | 416 | 45 | 90 | 42 | 75 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 12 | 45 | 37 |

| 11.0 / 15.0 | 750 | 180M | 467 | 50 | 100 | 48 | 105 | M30 | 50 | 300 | 250 | 350 | 19 | 5 | 14 | 51.5 | 42.5 |